Application:

An economy grade general service compressed sheet with NBR rubber binder for mild service in piping and equipment and OEM applications in steam, hydrocarbons and refrigerants. An economical alternative when service ranges and applications are not severe.

Composition:

DURLON® 7900, 7925 and 7950 contain high-strength aramid fibres bonded with high-grade nitrile (NBR) rubber.

Anti-stick properties:

Much effort has gone into improving the anti-stick release agents of all compressed DURLON® products. All DURLON® compressed gasket materials have passed the MIL-G-24696B Navy Adhesion Test (366°F/48 hrs).

Typical Physical Properties:

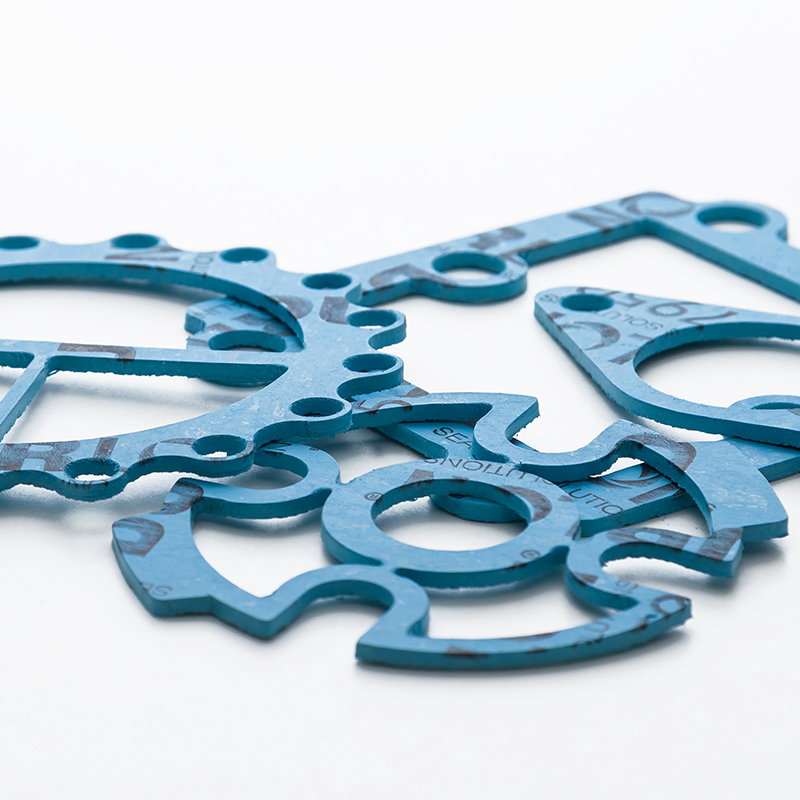

| Colour | 7900 – Off-White 7925 – Light Green 7950 – Blue |

| Fibre System | Aramid-Inorganic |

| Binder | NBR |

| Temperature Min Max Max, continuous |

-73°C (-100°F) 371°C (700°F) 260°C (500°F) |

| Pressure, max, bar (psi) | 83 (1,200) |

| Density, g/cc (lbs/ft3) | 1.7 (106) |

| Compressibility, % ASTM F36 |

7-17 |

| Recovery, % ASTM F36 |

40 |

| Creep Relaxation, % ASTM F38 |

20 |

| Tensile Strength across grain ASTM F152, MPa (psi) |

11 (1,600) |

| Fluid Resistance, ASTM F 146, IRM 903 Oil 5 hours at 149°C (300°F) Thickness Increase, % Weight Increase, % ASTM Fuel B 5 hours at 21°C (70°F) Thickness Increase, % Weight Increase, % |

0-15 15 0-10 12 |

| Sealability , cc/min ASTM F2378 (Nitrogen) Sealability, ml/hr ASTM F37 (Feul A) ASTM F37 (Nitrogen) |

0.05 0.03 0.5 |

| Gasket Factors m Y, psi Gb, psi a Gs, psi |

1/16” 1/8″ 3.0 3.2 3,347 (23.1) 3,385 (23.3) 497 (3.4) 486 (3.4) 0.226 0.276 3 (0.02) 0.4 (0.003) |

| Flexibility, ASTM F147 |

10x |