Application:

DURLON® 9000/9000N is used extensively in chemical, pulp and paper, food and beverage and the railroad tank car industries. It has been tested and approved for liquid chlorine, caustics, liquid oxygen, and high purity applications in the pharmaceutical industry (9000N for blood components manufacturing). DURLON® 9000 and 9000N are designed for applications where resistance to highly aggressive chemicals is required. Available in unpigmented white as style 9000N, both styles 9000 and 9000N, (including branding) conform to FDA requirements.

DURLON® 9000 has been proven through the “Test Protocol” of the Chlorine Institute and is listed as an acceptable gasket material for dry chlorine service (both liquid and gaseous) in Pamphlet 95, Edition 3 of the Chlorine Institute. Additionally, DURLON® 9000 was independently tested and approved for caustics service by a major chemical/chlorine manufacturer. Unlike generic glass fibre-filled PTFE, the shape of the fillers used in DURLON® 9000 do not allow wicking which can cause corrosion on flange faces.

DURLON® 9000/9000N has been independently tested and certified (BAM) for oxygen service at pressures up to 585 psi (40 bar) and temperatures up to 200°C (392°F), and for service in liquid oxygen. Gaskets for oxygen service can be supplied from distributor stocks, providing proper cleaning procedures for oxygen service are followed before installation.

Composition:

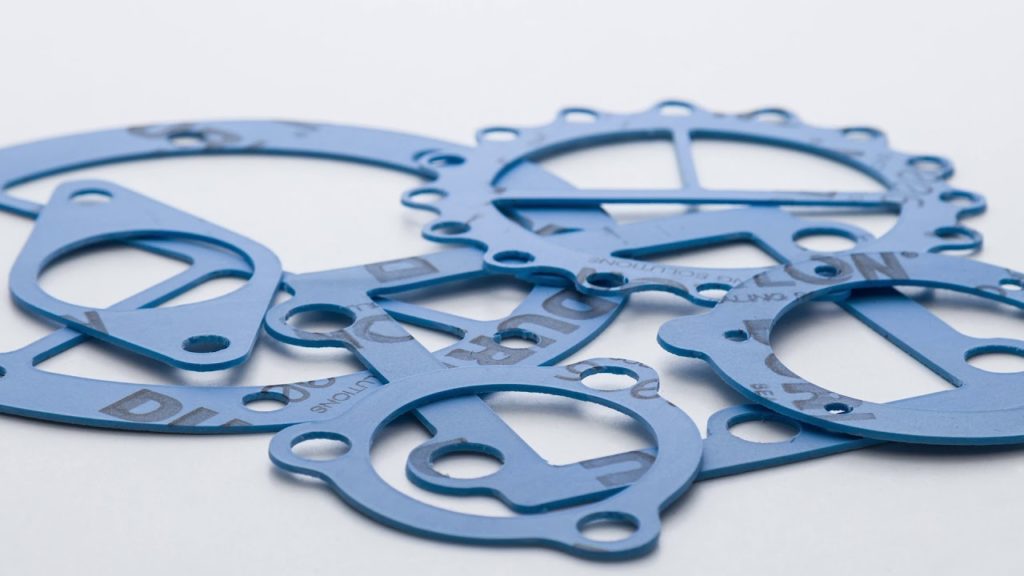

Various shapes of inorganic fillers have been homogeneously blended with pure PTFE resins to give DURLON® 9000 its physical and mechanical properties. It is suitable for use in steel flanges and will not exhibit the cold flow problems associated with virgin PTFE or the hardness problems of some other filled PTFE products. It cuts easily and separates cleanly from flanges after use.

Teflon Fluoroplastic Durlon 9000

Durlon® 9000 is made with Teflon™ fluoroplastic. Teflon™ is a trademark of The Chemours Company FC, LLC used under license by Triangle Fluid Controls Ltd.

Typical Physical Properties:

| Colour | 9000 – Blue 9000N – White |

| Filler System | Inorganic |

| Temperature Min Max Max, continuous |

-212°C (-350°F) 271°C (520°F) 260°C (500°F) |

| Pressure, max, bar (psi) | 103 (1,500) |

| Density, g/cc (lbs/ft3) | 2.2 (138) |

| Compressibility, % ASTM F36 |

8-16 |

| Recovery, % ASTM F36 |

40 |

| Creep Relaxation, % ASTM F38 |

30 |

| Tensile Strength across grain ASTM F152, MPa (psi) |

13.8 (2,000) |

| Sealability (Nitrogen), cc/min ASTM F2378 |

0.01 |

| Volume Resistivity, ohm-cm ASTM D149 |

1.0 x 105 |

| Dielectric Breakdown, kV/mm ASTM D149 |

16 (406) |

| Flexibility ASTM F147 |

5x |

| Gasket Factors m Y, MPa (psi) Gb, MPa (psi) a Gs, MPa (psi) |

1/16″ 1/8″ 2.2 4.6 1,937 (13.4) 1,639 (11.3) 639 (4.4) 495 (3.4) 0.22 0.262 55 (0.379) 65 (0.448) |

| TA-Luft (VDI Guideline 2440) Approved temperature of exposure: period of exposure: test pressure (hellum): leak rate: period of leak rate measured: |

180°C (356°F) 48 hrs. 1 bar (14.5 psig) 7.55E-6 mbar*l(m*s)24 hrs. |

| BAM – Oxygen Testing a) Gaseous oxygen: b)Liquid Oxygen: |

Up to 52 bar (754 psig) 260°C (500°F) |

| Pamplet 95, The Chlorine Institute | Listed table 3-1, for dry chlorine service and Table 3-3, for wet chlorine service |

| FDA | Conforms to the requirements of 21 CFR 177.1550 for food and drug contact |

| USP Class VI | 121°C (250°F) 30 min. |

| DNV-GL | Certificate NO. 13 560 – 14HH |