Technical Features

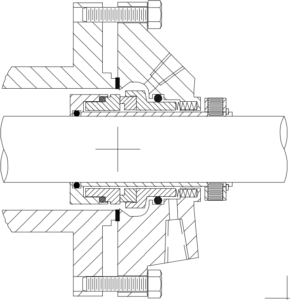

Cool running gland design provides clearances 10 times greater than the average clearance provided by other seal manufacturers’ designs, This feature maximizes the volume of flow around seal faces, resulting in a cooler, cleaner face environment, providing extended seal life.

Tangential flush connections positioned over the seal faces utilize the largest thru hole diameter available, supplying over 4 times the volume of straight drilled flush holes, providing maximum cooling and cleaning of seal faces maximizing seal life.

Interchangeable stationary faces enable application customization, resulting in stable, secure sealing, accommodating the widest range of operating conditions and applications in industry. Choose from:

- Monolithic, one-piece face designs that provide unparalled face stability under fluctuating system operating conditions, resulting in superior emission control capabilities.

- Two piece face designs that assure optimum seal performance for the most challenging, demanding environments where one piece face construction is vulnerable to premature failure.

Rugged, heavy-duty gland castings eliminate distortion related failures typically encountered on “low cost, light duty gland designs”.

Rotary inboard faces stabilized under compression are flexibly mounted utilizing o-rings for their shock and vibration absorption qualities. This eliminates premature fractures in the faces under thermal and mechanical shock that can cause catastrophic failures in other designs with faces under tension.

Balanced stationary cartridge design utilizes all static o-rings, which eliminates damage to the pump shaft/sleeve or seal normally caused by rotary pusher component or pusher cartridge type seals, allowing use of solid pump shafts that minimize deflection.

Positive hold, metal-centering clips center the seal in both the axial and radial directions.

Optional features:

- 2 piece stationary face

- Quench and drain feature

Choose from spare parts kits for field repair or the optional factory repair program. State of the art, easy-to-install design uses the least number of components, simplifying field repair, resulting in low life cycle costs.

All seals are pressure tested at the factory assuring 100% sealability during startup.

Application Data |

| Shaft speed: To 3600 RPM |

| Pressure: Vacuum to 400 PSI |

| Temperature: See O-ring limitations

|

Materials |

| Metal Parts: 316SS, Alloy 20, Hastelloy “C”, |

| Titanium |

| Springs: Hastelloy “C” |

| Faces: Combinations of Carbon, Sintered-Silicon |

| Carbide, and Tungsten Carbide |

| Elastomers: Viton, EPR, Kalrez, Aflas, Teflon |