Application:

Durlon® Spiral Wound Gaskets (SWG) are made with an alternating combination of a preformed engineered metal strip and a more compressible filler material which creates an excellent seal when compressed. The engineered shape of the metal strip acts as a spring under load, resulting in a very resilient seal under varying conditions.

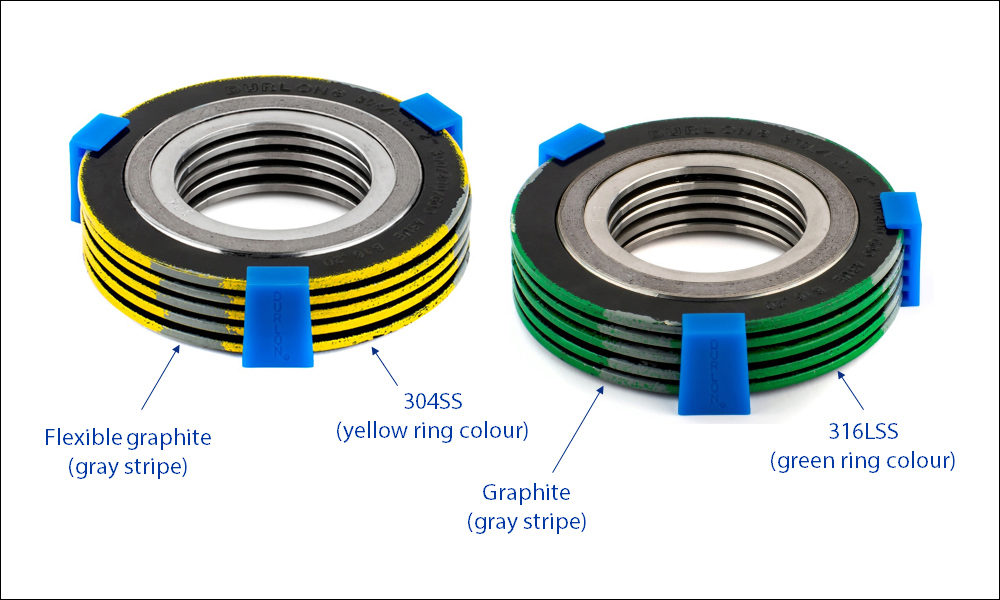

Composition:

The strip metallurgy and filler material can be selected to seal a wide range of applications. All Durlon® SWG styles have been engineered to precise manufacturing tolerances that allow for lower stress (bolt load) sealing compared to conventional spiral wound gaskets.

All Durlon® SWG are manufactured according to ASME B16.20 standards. Quality Assurance complies with API Specification Q1 and ISO 9001:2000.

Available Styles:

| Style D | Sealing element only consisting of preformed engineered metal and more compressible filler material Commonly used in tongue and groove or male and female flanges Can also be supplied with an inner ring as Style DI |

| Style DR | Sealing element (D) combined with a centering ring (R) which reinforces the gasket and acts as a compression stop Commonly used with standard raised face and full face type flanges Centering ring is electroplated which provides superior corrosion resistance compared to powder or liquid coating |

| Style DRI | Sealing element (D) combined with a centering ring (R) and an inner ring (I) which improves radial strength and protects the sealing element from erosion and inward bucking Commonly used with standard raised face and full face type flanges In accordance with ASME B16.20-2012, inner rings for all gaskets are recommended for all sizes, materials and classes. |